Do You Have A Construction Project We Can Help With?

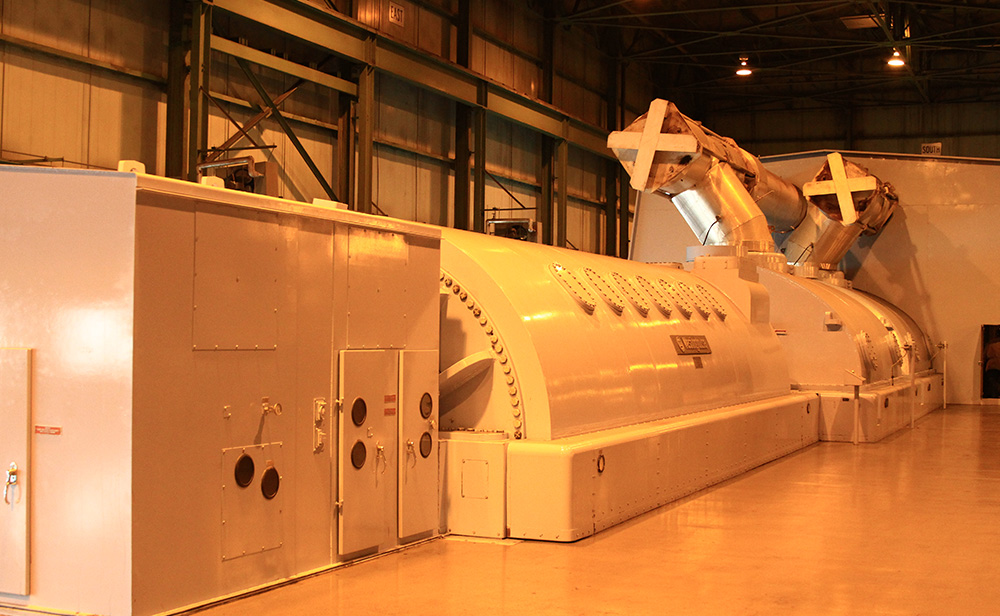

Steam Turbine

Maintenanance & Repair Solutions

At S.T. Cotter Turbine Services, Inc., we provide services for various types of steam turbine repair and maintenance requirements backed by our extensive turbine knowledge and global service reach. Our steam turbine services address everything from specific components to the overall health of your turbine system.

Our steam turbine supervisors have extensive experience working with the top domestic and European turbine equipment manufacturers.

Steam Turbine Services

The range of services we offer that address steam turbine maintenance and repair requirements includes:

-

Tool Sets

As a leader among steam turbine repair companies, we offer an array of turbine solutions, including innovative reverse engineering capabilities, spare parts packages, maintenance, and operational assistance.

Steam Turbine Upgrades

Through an integrated approach, we pinpoint and help implement the solutions you need for your plant, upgrade strategy, and budget. Efficient and effective steam turbine upgrades can enhance overall performance and expand the operational life of your turbines.

Steam Turbine Maintenance and Repairs

With our global capabilities, we are able to provide you with effective and fast steam turbine repair and maintenance services. Our specialized technicians are able to leverage the necessary resources and knowledge we possess to deliver the results you need.

Steam Turbine Parts

Regardless of whether you need a total steam turbine overhaul or simply one part addressed, we provide custom designed parts for various types of steam turbines. The precisely fabricated parts we employ solve the issues at hand and help promote and extend the service life of your steam turbine power system.

Steam Generator Maintenance and Repair Services

At S.T. Cotter Turbine Services, Inc. we provide comprehensive turnkey solutions for our customers. Not only does this include labor, turbine repairs, and technical direction, but also a full complement of steam turbine generator services, including electrical testing, re-wedges, rewinds, electrical diagnostics, excitation upgrades, and CO2 blasting.

Turbine Generator Maintenance

Per our customers’ requirements for electric utility sized generators, we provide the full range of visual inspections, logical testing, and specialty tests. The professional team of trained and highly skilled experts we retain at S.T. Cotter Turbine Services can meet the challenges of your project through the use of our considerable resources and experience.

Through the implementation of effective planning, we can help you keep your outage times to the minimum, leading to optimum production and efficiency.

Turbine Generator Technical Services

Our team of technical managers and professionals is highly experienced and able to provide efficient and effective solutions to the various complex and unique turbine generator issues that accompany your project. We provide expert technical direction for various requirements involving steam turbine generator inspections, repairs, overhauls, and upgrades.

We provide skilled steam generator maintenance, labor, mechanics, equipment, tools, and other services and resources for turnkey installation, and overhaul of generators and other rotating equipment.

Our specialists at S.T. Cotter Turbine Services provide extensive testing and inspection services, including visual inspections and electrical tests on steam turbine generator components to help ensure you can make the proper decisions about potential repairs.

Steam Turbines – Technical Direction

From start-up and project scheduling through training and post-completion manuals, S.T. Cotter Turbine Services, Inc. Technical Field Supervisors provide complete guidance on all aspects of your project. Our technical services provide optimum project support through complete training, engineering and best practices solutions. We take each customer through our proven processes of testing, training, procedure documentation and certification. We plan outages in Microsoft Project, Primavera P3 Contractor or Excel.

Our custom-developed training programs are renowned in the industry and focus on teaching your staff the principles of operation and maintenance, as well as maximizing your plant’s efficiency. We combine interactive classroom, hands-on and site-specific training for all levels of staff.

Mechanical Balance of Plant Contract (MBoP)

The nonelectrical auxiliary systems that make possible the efficient operation of various components of a power plant comprise a Mechanical Balance of Plant contract. The systems and components include:

- NOx Reduction Packages

- Fuel Gas Conditioning Systems

- Nitrogen Generation Packages

- Pressure Reduction Systems

- Fire Protection systems

- Compressed air systems

Electrical Balance of Plant Contract (EBoP)

- Auxiliary transformers

- Power transformers

- Circuit breakers

- Switchgear

- Surge arresters – deliver overvoltage protection

- Electrical busbars

Steam Path Services

S.T. Cotter has the competencies to repair, rebuild or replace steam path’s for various size steam turbines. S.T. Cotter can replace complete diaphragms, re-bucket and re-blade rotors with owner provided parts or S.T. Cotter provided. Low or high speed balance can be accomplished as well. Complete retrofit services of any OEM brand is also well within S.T. Cotter’s ability, to date over 35 retrofits have been accomplished.

Steam Turbines – Models Serviced

We have extensive experience and expertise in servicing the following steam turbines:

- Alstom Steam Turbines

- BBC Steam Turbines

- Elliot Turbines

- GE

- GE Lynn Steam Turbines

- Murray Steam Turbines

- Toshiba Steam Turbines & Valves

- Worthington Steam Turbines

- Westinghouse Steam Turbines

- Siemens Steam Turbines

- Boiler Feed Pump Turbines

Industrial Rigging Service Professionals with Experience

Quality rigging must be carried out by a seasoned team that has full understanding of the various components of the equipment involved in addition to the proper implementation of safety procedures. Our team understands all of these factors including how to obtain the necessary permits and zoning required to properly execute a project.

Our rigging professionals perform complicated relocation techniques and utilize critical safety measures to move items using specialized machinery and equipment. The various types of equipment employed in our rigging services can include forklifts, cranes, hoists, flat beds, gantries, ropes, high cube trailers, chains, skates, lifting bars, and blocking and steel plates.

Efficient Gas and Steam Turbine Rigging Results

The approach we take to performing technical rigging services results in reduced costs and shorter schedules for clients by removing the need to perform unnecessary crane mobilizations and/or jacking maneuvers.

Our Tooling Expertise

At S.T. Cotter Turbine Service, Inc., we have exceptional resources and capabilities allowing us to have the right tooling on hand prior to the commencement of your project. The tooling we offer is shipped from a private carrier to minimize costs and avoid shipping delays.

The tool sets we offer come in three distinct sizes as listed below:

“J” Tool Set

The J tool set enables complete major on a large frame steam or gas turbine in addition to a retrofit. It includes steel rigging with a maximum diameter of 1.25 inches as well as 5 ton chain falls. Within the tool set is also included 1.5 inch impact sockets, a set of hand tools, power tools, and precision measuring equipment for outside and inside, and hydraulics.

“S” Tool Set

The S tool set enables a minor steam or gas turbine outage, single LP, hot gas path, HP turbine, or generator outage. The S set includes the same tools as the J set except for the 1.5 inch sockets.

“C” set

The C tool set includes a complete set of pneumatics and hydraulics in addition to precision equipment up to 12 inches. It only has 1 inch impact sockets up to 2.5 inches and no 5 ton chain falls.

Our Tooling Expertise

The various tooling options we provide include impact sockets consisting of ¾ to 1-1/2 drive, chrome sockets (¾ and 1” drive), hydraulics (rams, hand pumps, pneumatic and electric pumps), hand tools (drill motors, grinders, wrenches, mag bases, Johnson/sleeve bars, saws), Allen wrenches, combination wrenches, and slug wrenches.

We also offer a wide range of rigging devices, including eyebolts, swivel eyebolts, shackles, and steel slings (3/8” to 1-1/4”), nylon lifting straps, chain falls (1, 2, and 5 ton), and come-a-longs.

The precision equipment our team offers includes inside and outside micrometers, taper gauges, dial indicators, extension meters, and taper gauges.

We also offer slug wrenches and castellated sockets in sizes of 1-1/2” to 4”.

The miscellaneous items comprising our tooling expertise include 2- and 4-wheeled hand trucks, small and large bolt/storage bins, pallet jacks, gantries, rotor/equipment stands, welders, tents, work tables, air hoses, machinery rollers, optical equipment, and more.

We deliver specialty tooling such as plasma cutters, grit blasting booths, stud/bolt heaters, torque multipliers, pneumatic bolt tensioners, torch kits, and more.

Our onsite inventory includes the lathe, Bridgeport, and surface grinder.